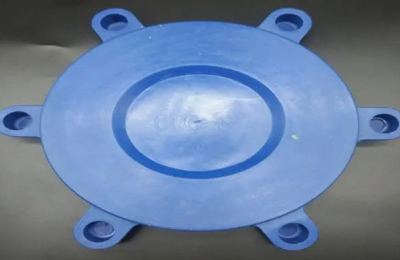

Large-diameter flanges

Large-diameter flanges are commonly used flat welded flanges and butt welded flanges. Threaded flanges do not have large diameters. In the actual production and sales, the proportion of flat welding products accounts for a lot. The structure and scope of use of flat welding large-diameter flange and butt welding large-diameter flange are different, and the characteristics and advantages that can be shown will be different, so they should be used for different ranges when using to ensure that the flange plays an important role. The rigidity of large-diameter flat welded flanges is poor, and it is suitable for occasions with pressure p≤4MPa; Butt welding flange, also known as high neck flange, has high rigidity and is suitable for occasions with high pressure and temperature. There are three types of flange sealing surfaces: flat sealing surfaces, which are suitable for occasions where the pressure is not high and the medium is non-toxic; Concave and convex sealing surface, suitable for occasions with slightly higher pressure; The sealing surface of the tongue and groove is suitable for flammable, explosive, toxic media and high pressure occasions. Flange fittings of different properties have good product performance in different fields, and the effects will be different when they are adapted to different occasions and spaces.

Theoretical calculation formula of large-diameter flange (carbon steel):

1.

Divide (D-B) by 2 = N.

2.

Reuse (D-N)×N×0.0246615×C ×0.001

(Note: D represents the outer diameter, B represents the inner diameter, N represents the width of the flange on one side, and C represents the thickness)

After the above two steps, the theoretical weight of the flange is obtained.

For example: carbon steel flange with an outer diameter of 2800mm, an inner diameter of 2600mm, and a thickness of 60mm

1.

(2800-2600)/2=100mm

2、 (2800-100)x100x0.0246615x0.06=399.5163KG

(Note: If it is a stainless steel flange, just replace the above 0.0246615 with 0.02491)